With the increase of prevalent dental disorders and the rise in technological expansions in dentistry, more and more dental labs are looking into CAD/CAM machines to boost their efficiencies.

By employing a dental milling machine, a dentist can design and create computer-generated prosthetics and make quality restorations. A dental milling machine produces dental crowns, bridges, removable dental prostheses, temporary prostheses, implant abutments, copings, completed dentures, etc.

With that in mind, dental labs must select the right dental milling machine. There’s no one-size-fits-all when it comes to milling machines. The mills vary in terms of size, production capabilities, and materials used. Therefore, buyers must ensure their preferred mill is capable of meeting their needs.

Applications of Dental Milling Machines

Dental milling machines have many applications in dental labs, including:

l Crown

In milling dentistry, dental milling machines work to design and create crown prosthetics using zirconia and e-max materials. These prosthetics work to permanently restore damaged crowns to their appropriate form and function. Dry milling is usually used for most zirconia milling, while wet milling is best for e-max materials.

l Veneer

A dental milling machine uses materials like zirconia, PMMA, and composite resin materials to construct a front-facial veneer to cover blemishes and other aesthetic issues. The permanent veneers produced boast great strength and durability and can withstand years of wear and tear. The dentist can use them for common teeth problems, such as cracked or chipped teeth and minor fractures. Usually, they’re custom-made to match the shape, size, and even color of the affected teeth.

l Bridge

Dentists can use dental milling machines to fabricate bridge restorations from various compatible materials, including e-max, zirconia, and PMMA (Polymethyl Methacrylate). The custom-made bridges can help solve a variety of dental cases (like missing teeth) and restore the natural look to the patient’s mouth/smile.

How to Select the Best Dental Milling Machines

Below, we have highlighted several factors that you should keep in mind when choosing the right dental milling machine for your dental lab.

l Machinable material

Before investing in a dental milling machine, it’s wise to know the type of material you want to mill. Machinable materials play a significant role in determining the machine requirements, including low-speed torque, high-speed horsepower, and spindle rpm. For instance, hard materials require low-speed torque and rigidity to minimize the effects of side thrust. On the other hand, soft materials need high speeds for finishing.

Machinable materials come in varying shapes, sizes, shades, and colors. The most common materials include Zirconia, Lithium Disilicate, Wax, Titanium, Glass Ceramic, Composite, etc. While most of these materials can be dry-milled, not all can be wet-milled. Furthermore, machines that excel in milling wax might not mill titanium bars very well.

l Indications

Another factor worth considering is indications supported by the milling machine. Most machines mill and grind inlay/onlay, crowns, telescopic crown, model plate, veneer, abutment, model cast, implant bars, and dentures, as well as bridges.

l Spindle speed

The speed of a dental milling machine is determined by its spindle, an encapsulated motor that spins the cutting tool. The speed of the spindle often varies depending on the type and size of the cutting tool being used, the machinable material milled, and the amount of material cut. Usually, dental mill machine manufacturers and CAM software programmers leverage industry-wide standards to choose spindle speeds that ensure the best tool life, cutting speeds, and cutting quality.

l Size

Dental milling machines come in three size variations, including table-top, bench-top, and freestanding. Table-top dental mills are small, portable, and effective at milling a single-unit block. Although many mills come with tool changers to swap burs during milling, table-top mills feature fixed tooling that must be manually swapped during the milling process. While these machines keep maintenance costs low, they have limited lifetime and tolerance.

Compared to table-top mills, bench-top machines are larger and heavier. They use heavy-duty screws to move the milling spindle or stock. Furthermore, they boast automatic tool changers and sometimes feature different tool positions for additional milling and other materials. Bench-top mills can mill a wide array of machinable materials, including glass ceramics.

Last, we have stand-alone or freestanding milling machines. They are not only expensive but large and made from the toughest materials. In the long run, they offer more tolerance than table-top or bench-top milling machines. Additionally, they can mill anything.

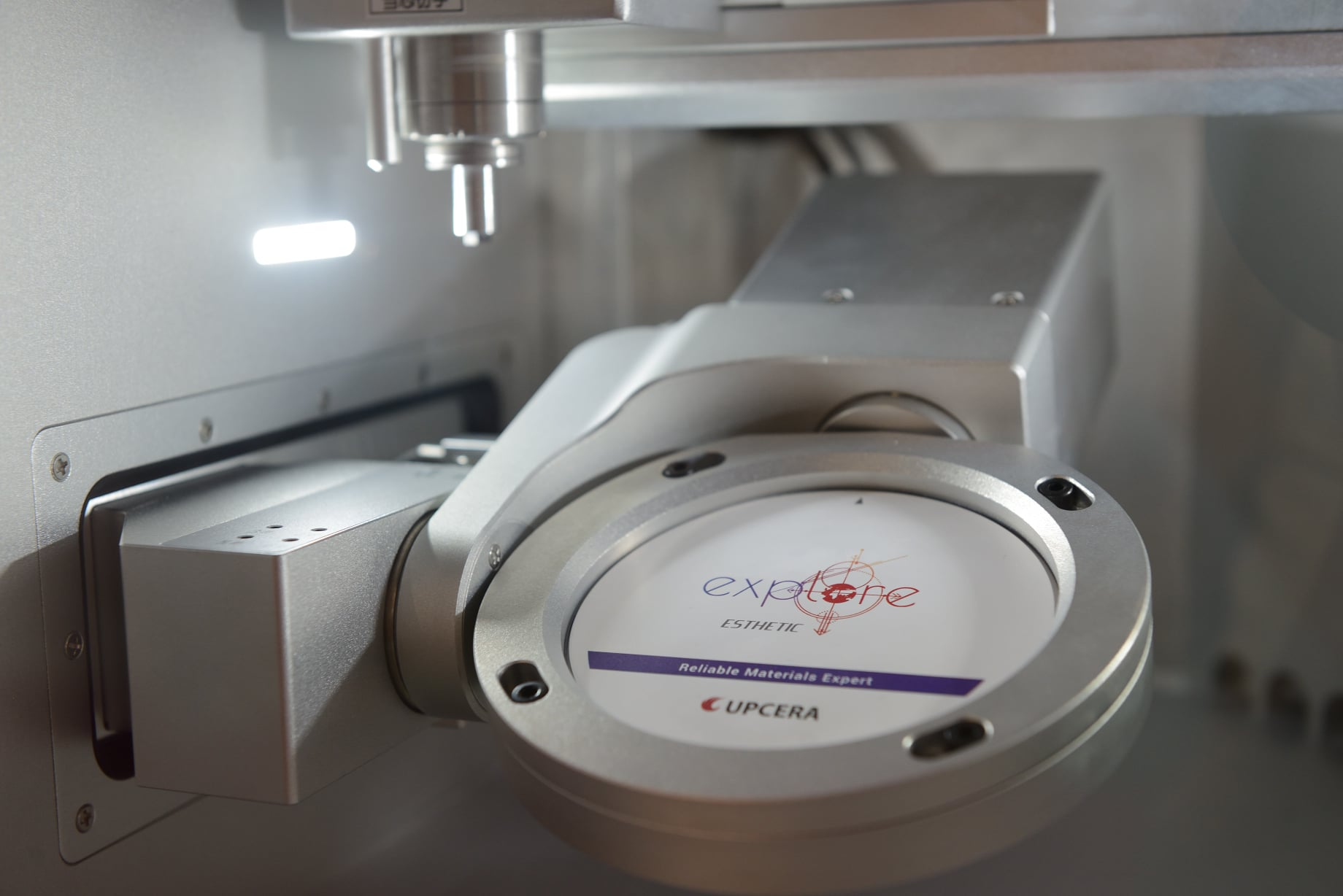

In addition to the highlighted factors, the dental milling machine voltage, processing speed, power consumption, and even weight can influence your choice of dental milling machines. Instead of finding the best milling machine, you can trust Upcera, which offers you the best option: the A51 dry milling machine. Ideal for milling zirconia, PMMA, and Wax, this 5-Axis dry milling machine processes orders with different indications and promises buyers fast processing for restorations.

Conclusion

Before buying any dental milling machines, buyers must understand that mills come in different sizes, shapes, and configurations. As such, they need to evaluate several factors, including mill performance, machinable materials, processing speed, and others, to make an informed purchase.

If you’re looking for the best dental solutions, look no further than Upcera. With a market presence in over 100 countries, Upcera promises customers and patients high-quality products and services that will meet all their dental care needs and leave them smiling.